Precautions for the installation of steel structure workshops

Installing steel structure workshops requires careful planning to ensure safety, durability, and compliance with regulations. Below are critical precautions to address during the installation phases to mitigate risks and optimize performance.

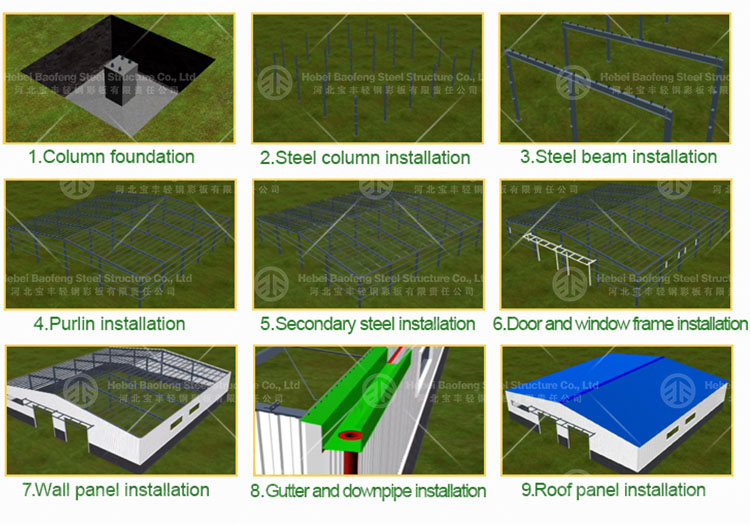

Installation Phase Precautions

1. Foundation Preparation

Load-Bearing Capacity: Conduct soil tests (bearing capacity ≥150 kPa) to determine foundation type (e.g., strip footings, pile foundations).

Anchor Bolt Placement:

Set anchor bolts in accurate positions (tolerance ±5 mm) using templates to align columns.

Embed bolts ≥200 mm deep with epoxy grout for stability.

2. Erection & Alignment

Column Verticality: Use plumb bobs/laser levels to ensure columns are vertical within 1/1000 slope.

Beam Leveling: Check beam horizontality with spirit levels to prevent uneven load distribution.

Temporary Bracing: Install diagonal bracing during assembly to stabilize the structure until permanent connections are complete.

3. Weather Protection

Rain/Snow Measures: Cover steel components with waterproof tarps during installation to prevent rust.

Temperature Control: Avoid welding/bolting in extreme cold (<5°C) or heat (>40°C)**; preheat steel if necessary.

4. Safety During Installation

Fall Protection: Use scaffolding, harnesses, and guardrails for heights >2 m.

Heavy Equipment Handling: Employ cranes/crane operators with load charts to prevent overloading.

Fire Prevention: Keep fire extinguishers nearby during welding/cutting.

Post-Installation Inspections & Maintenance

1. Structural Integrity Checks

Visual Inspections: Look for cracks, deformations, or loose bolts after installation.

Load Testing: Verify roof/wall loads with sandbags or water weights to ensure stability.

2. Corrosion & Rust Monitoring

Regular Inspections: Check for rust spots (especially joints, fasteners) every 6–12 months.

Repainting: Reapply anti-rust paint every 5–10 years or after severe weather exposure.

3. Maintenance of Fasteners & Connections

Tighten Bolts Annually: Prevent loosening due to vibrations (e.g., from machinery).

Replace Damaged Components: Swap corroded bolts or cracked welds immediately.

Compliance & Documentation

Permits & Codes: Ensure compliance with local building codes (e.g., IBC, GB50017 in China, Eurocode in Europe).

As-Built Drawings: Submit detailed drawings with measurements, material specs, and load calculations for future reference.

Key Takeaways

Prioritize load calculations and safety factors to prevent structural failure.

Use high-quality materials (galvanized steel, high-strength bolts) and corrosion-resistant coatings.

Follow precise installation procedures (foundation anchoring, beam alignment) to ensure stability.

Conduct regular inspections to maintain longevity and safety.

By adhering to these precautions, steel structure workshops can achieve optimal performance, safety, and cost-efficiency for decades.

Thể loại

blog mới nhất